Sorry. We did not find anything.

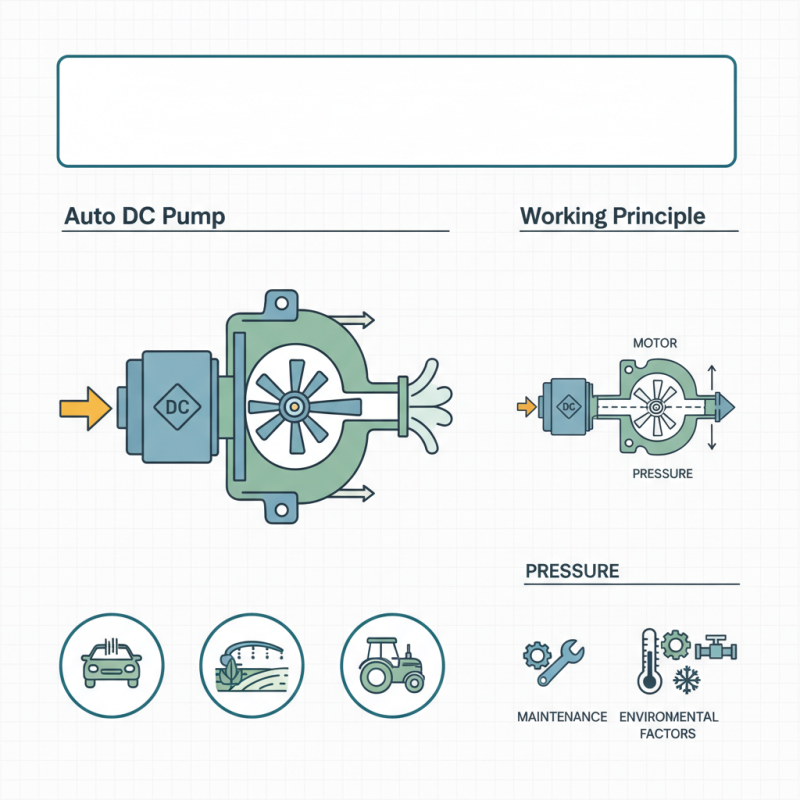

What is an Auto DC Pump and How Does It Work?

An Auto Dc Pump is a critical component in various applications. These pumps operate using direct current, facilitating efficient fluid transfer. They are prevalent in automotive, agricultural, and industrial settings. Understanding how they work is essential for users and professionals alike.

The design of an Auto DC Pump is relatively simple. It typically includes a motor, impeller, and housing. The motor uses direct current to drive the impeller, creating suction and pushing fluid. This process is efficient, often reducing energy consumption. Yet, occasional maintenance is necessary for optimal performance. Users may overlook this, leading to underperformance.

Moreover, the effectiveness of Auto DC Pumps can vary. There may be challenges in specific environments, like extreme temperatures. These factors can influence the pump’s longevity and reliability. Being aware of potential drawbacks is important. It helps users make informed decisions. Understanding the nuances of an Auto DC Pump can lead to better usage and maintenance practices.

What is an Auto DC Pump?

An Auto DC Pump is a specialized pump that uses direct current (DC) power for its operation. This type of pump is favored in various applications, such as solar-powered systems. A notable feature is its energy efficiency, which can be over 90%, outpacing many traditional AC pumps. Industry reports indicate that DC pumps are becoming increasingly popular in renewable energy projects, reflecting a growing trend towards sustainable solutions.

The design of Auto DC Pumps allows them to operate quietly, reducing noise pollution significantly. They are compact, making installation easier in constrained spaces. These pumps often use brushes or brushless motors, with brushless models offering longer lifespans. However, some users report challenges with the initial setup. It’s essential to ensure proper voltage and current to avoid performance issues.

Moreover, the versatility of these pumps allows for various uses, from hydroponics to aquariums. Yet, users should consider factors like maintenance and compatibility with different systems. Technical challenges can arise, especially regarding power management. Observing feedback from users, it's clear that while they offer many advantages, understanding specific needs before purchase is crucial.

Key Components of an Auto DC Pump

An Auto DC Pump operates using direct current electricity. It is designed for various applications, ranging from aquariums to irrigation systems. The key components of an Auto DC Pump include the motor, impeller, and the control unit. Each element plays a critical role in the pump's operation.

The motor is the heart of the system. It converts electrical energy into mechanical energy. Most of the time, it runs quietly and efficiently. The impeller, attached to the motor, helps to move the fluid. It creates the necessary pressure and flow. Without a well-designed impeller, the pump could lose its effectiveness and struggle to perform.

The control unit is vital as well. It regulates the pump's operation based on different conditions. This unit can ensure that the pump runs only when necessary, improving energy efficiency. However, if the control unit malfunctions, the pump might run continuously, causing inefficiencies and potential damage. It’s essential to monitor these components closely for optimal performance.

What is an Auto DC Pump and How Does It Work? - Key Components of an Auto DC Pump

| Component | Description | Function |

|---|---|---|

| DC Motor | Converts electrical energy into mechanical energy | Drives the pump mechanism |

| Pump Head | The part of the pump that creates pressure | Moves fluid through the system |

| Control Circuit | Electronics that regulate pump operation | Ensures efficient and safe operation |

| Filter | Removes impurities from the fluid | Protects the pump and downstream components |

| Housing | Outer casing that protects the internal components | Provides structural integrity |

How Does an Auto DC Pump Operate?

An Auto DC pump is a specialized pump that uses direct current (DC) power for its operation. It typically functions efficiently in various applications, making it suitable for both residential and industrial use. These pumps are designed to work in environments where traditional AC power is not available or desirable.

The operation begins when electrical energy is supplied to the pump motor. This power activates the impeller, creating suction. As water or fluid enters the pump, it is pushed through the discharge port. The efficiency of these pumps can reach up to 90%, which is significant compared to conventional pumps. A report by the U.S. Department of Energy states that optimizing pump efficiency can save industries millions annually.

Tips: Ensure the power supply matches the pump requirements. Using an improper voltage could lead to performance issues. Regular maintenance is crucial. Check for wear and tear, as inefficient operation can go unnoticed.

Auto DC pumps can be vulnerable to overheating if not adequately ventilated. A lack of airflow can cause motor damage. Monitoring the pump's operating temperature can help preempt failures. Avoid placing these pumps in confined spaces without proper airflow. Always prioritize safety and efficiency in operational setups.

Applications of Auto DC Pumps in Various Industries

Auto DC pumps are widely used across various industries due to their efficiency and versatility. In agriculture, they irrigate fields with precision. These pumps can adapt to solar energy, making them cost-effective for remote areas. Farmers rely on them to maintain crops without relying on grid power. Water supply becomes sustainable, reducing costs and environmental impact.

In the automotive sector, auto DC pumps assist in fluid transfer and cooling systems. They're compact and lightweight, fitting easily in various designs. These pumps operate quietly, improving vehicle comfort. However, their reliance on electronic control can lead to issues in extreme conditions. Regular maintenance is essential to ensure their reliability.

In industrial applications, they manage fluid movement in manufacturing processes. Their capability to function under various pressures is beneficial. Still, operators must address challenges like potential overheating. Efficient management is crucial for optimal performance.

Advantages of Using Auto DC Pumps Over Traditional Pumps

Auto DC pumps have gained popularity in various applications due to their efficiency and versatility. One major advantage is energy efficiency. They operate on direct current, which often leads to lower energy consumption compared to traditional pumps. This can significantly reduce electricity costs over time. These pumps generate less heat and can maintain optimal performance without overstraining the system.

Another key benefit is their compact design. Auto DC pumps are smaller and lighter than conventional pumps. This makes them easier to install in tight spaces. Their portability can be advantageous in mobile applications where space is limited. Additionally, many models include built-in control features that enhance user convenience.

However, it's important to consider some limitations. While auto DC pumps are energy-efficient, they may not be suitable for all scenarios. Their reliance on direct current can be a drawback in areas where AC power is standard. Additionally, the initial investment can be higher than that of traditional pumps. Users need to evaluate their specific requirements to determine if the benefits justify the costs.

Comparison of Auto DC Pumps and Traditional Pumps in 2023

This chart illustrates the performance metrics of Auto DC Pumps compared to Traditional Pumps in 2023, highlighting their efficiency, power consumption, lifespan, and cost advantages.