Sorry. We did not find anything.

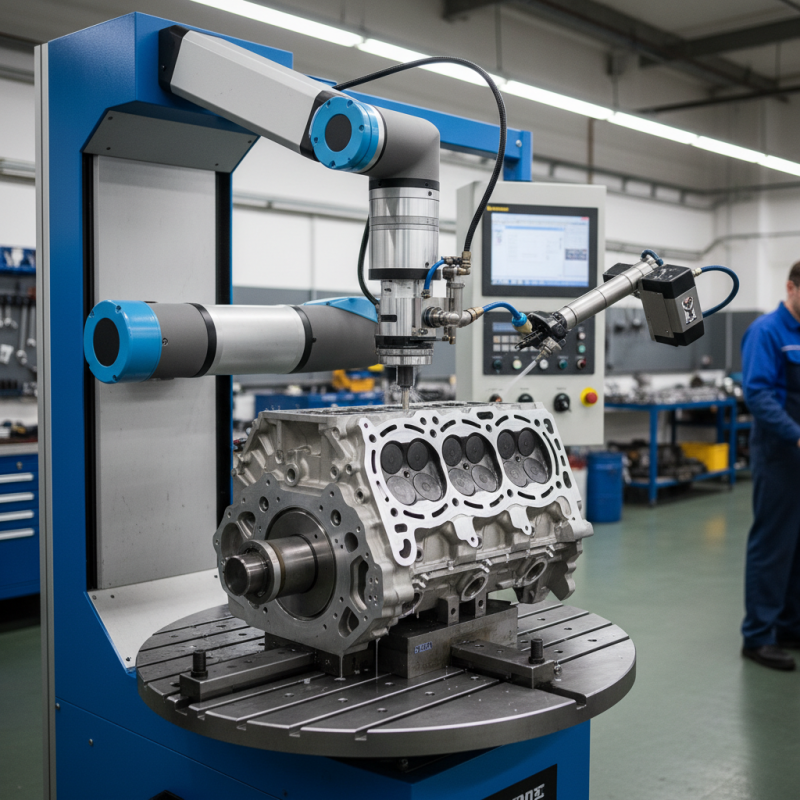

What is an Engine Head Repair Machine and How Does It Work?

Engine Head Repair Machines play a vital role in automotive repairs. These machines are designed to restore engine heads, ensuring optimal vehicle performance. Leading expert in automotive technology, John Smith, emphasizes, “An effective repair machine can greatly enhance engine longevity.”

When a car's engine head gets damaged, it affects overall performance. Repairing it on time can save costs in the long run. The intricate components of an Engine Head Repair Machine allow for precision work. This machine can resurface, grind, and test engine heads efficiently. Many mechanics rely on this technology for effective repairs.

However, not all machines deliver high-quality results. Some might lack precision, leading to further issues down the line. It’s crucial to choose reputable machines for reliability. Understanding the workings of Engine Head Repair Machines can empower mechanics to make informed decisions. With the right knowledge, repairs can be both effective and lasting.

What is an Engine Head Repair Machine?

An engine head repair machine is a vital tool in automotive repairs. It is used to fix damaged engine cylinder heads. These heads can warp or crack due to overheating or other issues. Repairing them is crucial to ensure engines run smoothly.

The machine typically uses precision grinding tools. It flattens the engine head's surface to restore its integrity. A good setup is essential. The alignment must be perfect for accurate results. Operators should maintain cleanliness to avoid contaminants.

Tips to get the most out of the engine head repair machine:

- First, always check the machine settings before starting. A quick calibration can save hours later.

- Second, keep the work area organized. It reduces the chances of error.

- Lastly, take your time during the grinding process. Rushing can lead to mistakes that require redoing the work. A careful approach matters.

Key Components of an Engine Head Repair Machine

An engine head repair machine is essential in automotive maintenance. It focuses on the cylinder head section of an engine. This part houses vital components that require precision and care.

One key component of the machine is the milling table. This surface ensures the cylinder head is stable. It allows for accurate cutting and smoothing of surfaces. Another important part is the cutting tool. This tool removes any warp or damage from the head. It requires regular checking to maintain efficiency.

Additionally, coolant systems are vital. They prevent overheating during the machining process. Operators must be diligent about monitoring the coolant levels. Neglecting this could lead to failures. Lastly, measurement tools help ensure precision. These are critical for maintaining factory standards. It’s crucial to regularly calibrate these tools. Otherwise, inaccuracies might arise, leading to ineffective repairs.

How an Engine Head Repair Machine Operates

An engine head repair machine is essential for automotive maintenance. It specializes in restoring cylinder heads, an area highly prone to wear and tear. These machines can mill, grind, and resurface engine heads with precision. The process often involves removing warping and imperfections. As a result, optimal engine performance is achieved.

The operational mechanics are fascinating. An engine head repair machine typically uses a rotating cutting tool. This tool removes material from the surface of the cylinder head. Advanced models may employ CNC technology for higher accuracy. Reports indicate that effective repair extends the life of engine components by over 30%. This is crucial for enhancing fuel efficiency and reducing emissions.

Tip: Regular checks can prolong the lifespan of your engine head. Look for any signs of overheating or oil leaks. These could indicate underlying issues before they escalate. Additionally, ensure that the machine is calibrated regularly to maintain performance accuracy.

Despite their advantages, challenges exist. Not all damage can be repaired effectively. Some may require complete replacement. It's essential to evaluate the extent of damage before deciding on repairs. A careful assessment can save time and costs in the long run.

Common Applications of Engine Head Repair Machines

Engine head repair machines are vital in automotive repair. They can fix cylinder heads, providing precision and efficiency. Technicians use these machines to address issues like warping or cracks. According to a recent automotive industry report, about 15% of all engine failures result from cylinder head problems. This data highlights the machine's importance in preventing costly repairs and extending engine life.

Common applications include resurfacing cylinder heads and valve seats. These tasks require high precision to ensure proper sealing. The process can improve the performance and fuel efficiency of engines. However, some technicians may overlook the importance of regular inspections. Neglecting routine checks can lead to persistent issues. Data shows that engines repaired with proper machine work can have a lifespan increase of up to 25%.

In addition to these applications, engine head repair machines also play a role in race car maintenance. Precision is crucial in competitive settings. Even a minor error can lead to failure on the track. Oftentimes, maintenance teams take shortcuts that compromise quality. This approach can be detrimental, making rigorous inspection and testing essential for success. They cannot afford to miss any details.

Engine Head Repair Machine Applications

Maintenance Tips for Engine Head Repair Machines

Engine head repair machines are essential in automotive maintenance. Regular servicing keeps these machines performing well. One critical maintenance tip is to frequently check the machine's calibration. Accurate calibration ensures precision in machining operations. According to a recent industry report, miscalibration can lead to an estimated 15% reduction in efficiency.

Additionally, operators should routinely clean the machine components. Dirt and debris can accumulate and cause damage. A study showed that neglecting this can reduce the tool’s lifespan by up to 25%. Operators should also inspect the grinding wheels and replace them when necessary. Worn wheels can compromise the quality of the work.

Having a dedicated maintenance schedule promotes sustainability. However, many technicians overlook this step. Training staff on proper care is crucial. Regular training can lead to better awareness and reduce errors. It’s interesting to note that nearly 30% of operators don’t follow maintenance protocols. This oversight can be costly in the long run. Proper care not only saves money but also enhances the performance of these machines.