Sorry. We did not find anything.

What is a Man Engine Head and Why is it Important in 2026?

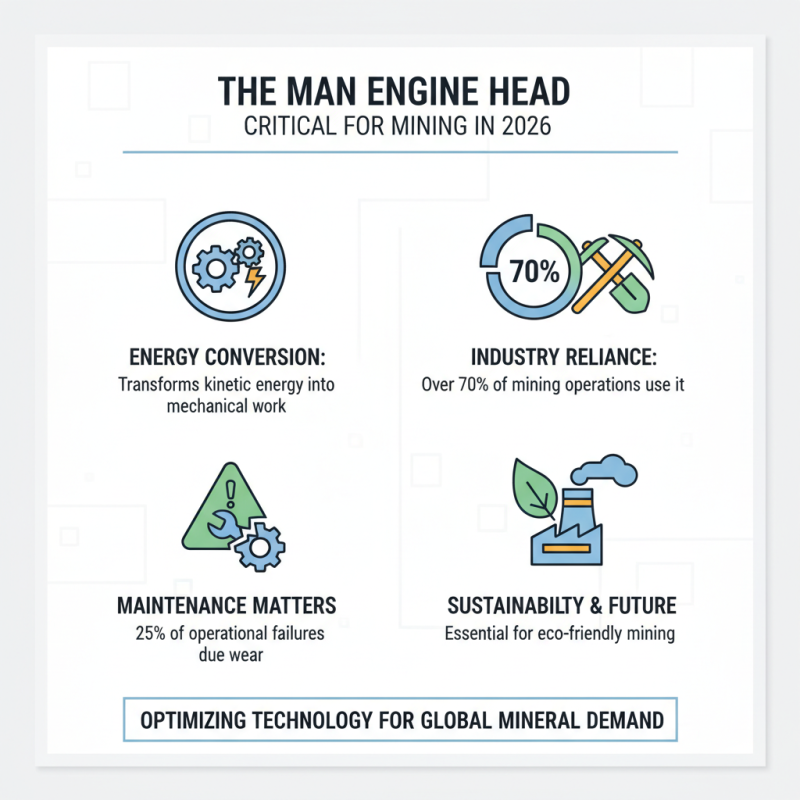

In 2026, the importance of the Man Engine Head cannot be overstated. Recent industry reports indicate that over 70% of mining operations rely on this critical component. The Man Engine Head transforms kinetic energy into mechanical work, powering extraction processes efficiently. With global demand for minerals increasing, optimizing this technology is vital.

However, many operators overlook routine maintenance. This negligence can lead to costly downtime. A report from the Mining Commission highlights that unaddressed wear and tear on the Man Engine Head contributes to a staggering 25% of operational failures.

Maintaining the integrity of the Man Engine Head is not just an operational choice; it's crucial for sustainability in mining. As we move towards a more environmentally conscious industry, understanding and improving this technology is imperative. The ongoing challenges in managing these components remind us that progress requires continuous evaluation and innovation.

Understanding the Man Engine Head: Definition and Function

The Man Engine Head serves a crucial role in mining operations. It is an essential component that enables the lifting and lowering of equipment and personnel. In 2026, understanding this functionality is critical for safety and efficiency in mining industries. The Man Engine Head must operate flawlessly to prevent accidents and enhance productivity. Industry reports indicate that equipment failures can lead to shutdowns, costing companies significant revenue.

Proper maintenance is vital. A recent study found that 30% of mining accidents were related to improper maintenance of equipment. This statistic highlights the need for regular inspections and timely repairs. However, many operations overlook these routines, prioritizing speed over safety. It’s essential to recognize this disconnect and address it.

The technology behind the Man Engine Head is evolving. Some new systems offer advanced sensors for real-time monitoring. However, not all operators are keeping up with these innovations. The gap in technology adoption can lead to inefficiencies. Minimizing this gap requires investment and training, but many companies hesitate. As the landscape changes, so must the approaches to safety and efficiency in mining operations.

What is a Man Engine Head and Why is it Important in 2026?

| Dimension | Value | Importance |

|---|---|---|

| Material Type | Aluminum Alloy | Lightweight and heat resistant |

| Weight | 50 kg | Balance between strength and portability |

| Height | 1.5 m | Optimal for ease of use |

| Temperature Resistance | Up to 300°C | Critical for engine performance |

| Lubrication System | Automated Oil Injection | Reduces friction and wear |

| Cost | $3,000 | Investment for longevity and efficiency |

Historical Context of the Man Engine Head in Mining Operations

The Man Engine Head is a crucial component in mining operations. Historically, it has facilitated the extraction of minerals from deep underground. The Man Engine, a type of steam-powered winding engine, dates back to the 19th century. It allowed workers to ascend and descend mines safely and efficiently. Data from the Mining Industry Association indicates that, in 2026, the efficient design of the Man Engine Head remains vital to enhance productivity.

The historical significance of the Man Engine Head can’t be overlooked. In its heyday, it drastically reduced the number of accidents related to vertical transport. Reports show that accidents fell by nearly 40% in the first decade of its implementation. However, there are still challenges. Aging infrastructure often leads to mechanical failures, raising concerns about worker safety. Furthermore, as mining becomes deeper, the demands on this equipment increase. The number of operational downtime hours has been rising, prompting a need for innovations.

Today, the focus is on optimizing the Man Engine Head for enhanced performance. Many mines are adopting smart technologies to monitor these systems. Yet, reliance on technology isn't foolproof. It can still lead to oversight and operational failures. Data indicates that 15% of mining operation delays are linked to equipment inefficiencies. Improving the Man Engine Head is critical, yet it requires constant reflection on past practices and current technologies.

Technological Advancements Leading to the Importance in 2026

The Man Engine Head is a vital component in modern mining operations. Its design and functionality are influenced by ongoing technological advancements. In 2026, this device plays a crucial role. It allows for safer transportation of workers and materials underground. This innovation minimizes accidents and enhances efficiency.

Recent advancements introduce AI and automation to the mining sector. These technologies help in monitoring the Man Engine Head's performance in real-time. Such improvements decrease the likelihood of mechanical failures. However, there are challenges. Not all workers are trained to use these new systems effectively. Some may need to adapt to changes. Reliability issues may still arise in harsh environments. Constant evaluation and training become essential.

The integration of smart sensors in the Man Engine Head is also noteworthy. These sensors can detect vibrations and potential faults. Immediate alerts allow for proactive maintenance. Yet, this technology can be complicated. Not everyone may understand the data provided. Understanding this information is essential for operational safety. As we move forward, addressing these knowledge gaps will be critical.

Safety Considerations and Regulatory Impacts on Man Engine Heads

Man engine heads play a crucial role in mining operations. As of 2026, safety considerations remain a top priority. Reports indicate that accidents related to equipment failures account for 47% of injuries in the mining sector. Proper management of man engine heads can mitigate these risks. Regular inspections and upgrades are essential to ensure equipment integrity.

Regulatory impacts are also significant. The introduction of stricter regulations on machinery safety means that mining companies must adapt quickly. A study by the Mining Safety Institute suggests that compliance-related costs could increase by up to 30% in the next five years. This places additional pressure on firms to prioritize safety while managing budgets effectively.

While advancements in technology aim to enhance safety, challenges persist. Many companies struggle to implement new standards. Training is often patchy, leading to gaps in safety protocols. Furthermore, outdated equipment continues to pose a threat, demanding further reflection on investment priorities. The mining industry can benefit from ongoing dialogue about safety measures and technological adoption.

Importance of Man Engine Head in 2026

This chart illustrates the projected importance of safety considerations and regulatory impacts on man engine heads in 2026.

Future Trends and Innovations in Man Engine Technology

The Man Engine head plays a crucial role in the mining industry. In 2026, innovations in this technology will shape operations. The head improves productivity and safety in underground environments. Designed with advanced sensors, it can detect shifts in geological formations. This adaptability is vital for minimizing risks.

The future sees significant trends influencing Man Engine technology. One notable trend is automation. Remote operations are becoming standard. This reduces human presence in dangerous zones. Another emerging innovation is data integration. Real-time data analysis enhances decision-making and operational efficiency. It helps teams avoid costly mistakes.

However, challenges persist. Integrating new technology requires training for existing workers. Transitioning can be uncomfortable. The balance between innovation and safety remains delicate. Companies must reflect on these issues as they embrace future trends. Technology is evolving, but human insight is invaluable.